Cuscinetti compositi con flangia senza olio MXB-DUF

Cat:Cuscinetto senza olio

Cuscinetto composito senza olio MXB-DUF, noto anche come boccola SF-1F, che è un cuscinetto scorrevole laminato con una piastra di acciaio come bas...

Guarda i detagli

Se l'attrezzatura per macchinari è paragonata a un "corpo umano" in movimento, cuscinetti auto-lubrificanti Gioca il ruolo combinato delle articolazioni e del sistema di cartilagine nel corpo umano: sono sia i mozzi fondamentali che sostengono il movimento sia i "Guardiani della lubrificazione" che riducono l'attrito e gli impatti ammortizzanti. Questo ruolo è incorporato nei seguenti tre aspetti:

Giunti: il perno per carico e movimento

Le articolazioni umane collegano le ossa, i carichi di orso e le forze di trasmissione; Allo stesso modo, i cuscinetti auto-lubrificanti si trovano nei nodi chiave di trasmissione meccanica (come alberi rotanti e barre di collegamento), intraprendendo le funzioni della trasmissione del carico e della guida del movimento.

l Elevata capacità di carico: proprio come l'articolazione del ginocchio supporta il peso del corpo, i cuscinetti in ottone ad alta resistenza con una massima pressione di 30-50 MPa possono resistere a pressioni estreme nei macchinari minerari, simile a come la cartilagine articolare disperde lo stress attraverso fibre di collagene ad alta densità.

l Flessibilità del movimento: il coefficiente di attrito basso (0,08-0,12) dei cuscinetti garantisce che l'attrezzatura funzioni in modo flessibile come le articolazioni umane, evitando la perdita di energia a causa di "balbuzie".

Cartilagine e fluido sinoviale: sinergia dell'auto-lubrificazione e resistenza all'usura

La cartilagine umana secerne il fluido sinoviale per ridurre l'attrito, mentre il materiale della matrice (come l'ottone ad alta resistenza) e i lubrificanti solidi incorporati (grafite, disolfuro di molibdeno) di cuscinetti auto-lubrificanti simula questo "meccanismo di lubrificazione dinamica"::::

l Ruolo della cartilagine: l'elevata durezza (HB 180-220) e la resistenza all'usura (velocità di usura 0,5 × 10⁻⁴ mm³/(n · m)) di ottone ad alta resistenza assomigliano alla resistenza di compressione e al taglio della cartilagine, proteggendo la matrice dall'usura diretta.

l Ruolo fluido sinoviale: i lubrificanti incorporati sono uniformemente rilasciati sotto il riscaldamento attrito, formando un film di trasferimento a spessore nanometro (circa 1-5 μm), simile allo strato protettivo formato dal fluido sinoviale tra le superfici articolari, raggiungendo lubrificazione continua senza "approvvigionamento di olio aggiuntivo".

Sistema immunitario: adattabilità ambientale e potenziale di auto-riparazione

Le articolazioni umane possono adattarsi alle variazioni di temperatura e resistere all'erosione infiammatoria, mentre i cuscinetti auto-lubrificanti affrontano condizioni di lavoro complesse attraverso la progettazione del materiale:

l Resistenza alla corrosione: gli elementi in alluminio e manganese in ottone ad alta resistenza formano un film passivo, resistendo all'acido, alcali e alla corrosione dell'acqua di mare (con un miglioramento del 40% della resistenza alla corrosione su ottone stagno), simile ai componenti antibatterici del liquido sinoviale.

l Resistenza a fatica: i cuscinetti rimangono stabili in frequenti start-stop o carichi di impatto (resistenza alla fatica ≥200 MPa), simile a come le articolazioni umane riparano il micro-danno attraverso la rigenerazione della cartilagine.

Confronto dei casi: cuscinetti falliti contro artrite

| Manifestazione di fallimento | Fallimento del cuscinetto auto-lubrificante | Artrite umana |

| Aumento dell'attrito | Il coefficiente di attrito sale superiore a 0,3, aumentando il consumo di energia del 15% | Fluido sinoviale ridotto, dolore esacerbato durante l'attività |

| Danno strutturale | L'usura a matrice porta a crepe, riducendo la capacità di portata del carico del 30% | Abbigliamento da cartilagine, attrito osseo diretto che causa infiammazione |

| Ridotta adattabilità ambientale | Insufficienza di ossidazione del lubrificante, resistenza alla corrosione ridotta | Movimento limitato dopo esposizione articolare a freddo o infezione |

I cuscinetti auto-lubrificanti, come un "sistema articolare intelligente" per i macchinari, utilizzano ottoni ad alta resistenza come "osso" e lubrificanti solidi come "fluido sinoviale" per ottenere un funzionamento efficiente e di lunga durata senza intervento esterno. Questo design non solo imita la squisita sinergia dei sistemi biologici, ma supera anche i limiti fisiologici delle prestazioni (come le temperature resistenti fino a 300 ° C e pressioni fino a 50 MPa), guidando le attrezzature industriali verso un'evoluzione più affidabile e autonoma.

Cuscinetto composito senza olio MXB-DUF, noto anche come boccola SF-1F, che è un cuscinetto scorrevole laminato con una piastra di acciaio come bas...

Guarda i detagli

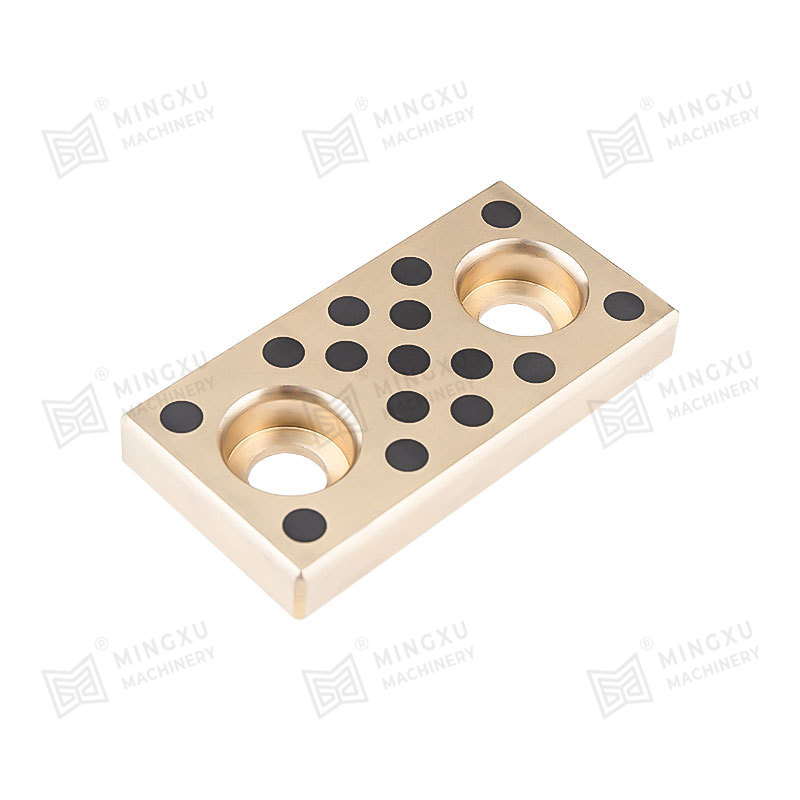

Lo skateboard MXB-JESW è uno skateboard per carichi pesanti resistente all'usura con 2 fori e 4 fori. È un prodotto standardizzato ed è compat...

Guarda i detagli

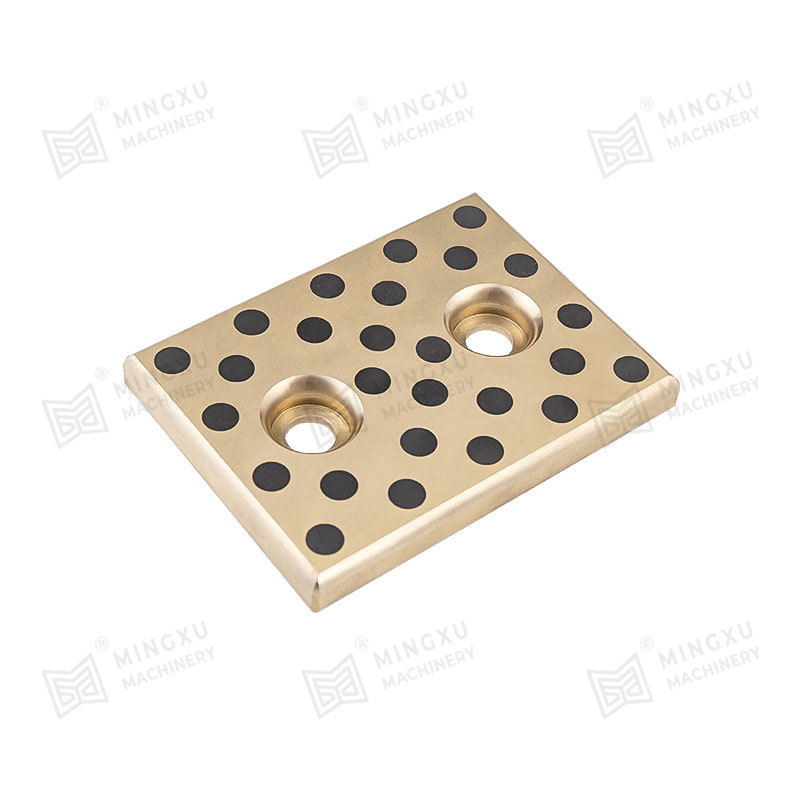

Le piastre antiusura autolubrificanti MXB-JOLP hanno buone proprietà autolubrificanti e non richiedono lubrificazione esterna. Questo prodotto ha una ...

Guarda i detagli

La piastra antiusura autolubrificante MXB-JSP è adatta per macchine per stampaggio a iniezione, stampi per stampaggio automobilistico, stampi per p...

Guarda i detagli

La boccola di guida standard MGB9834 DIN9834 è conforme allo standard DIN9843 ed è adatta per matrici per stampaggio automobilistico europeo. È pro...

Guarda i detagli

Le boccole di guida per iniezione senza olio MJGBF sono componenti utilizzati nel processo di stampaggio a iniezione di materie plastiche per migli...

Guarda i detagli

MX2000-1 graphite embedded alloy bearing, MX2000-1 graphite scattered alloy bearing is an improved product of JF800 bimetallic bearing. It has the pre...

Guarda i detagli

The bimetallic slide plate with wear-resistant alloy sintered on three sides is a new type of self-lubricating plate. Compared with the general single...

Guarda i detagli

SF-2X boundary lubricated bearing is based on steel plate, with sintered spherical bronze powder in the middle, modified polyoxymethylene (POM) rolled...

Guarda i detagli

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

Guarda i detagli

Contattaci