Metà cuscinetto autolubrificante MXB-JFFB

Cat:Cuscinetto autolubrificante

I semicuscinetti autolubrificanti MXB-JFFB si riferiscono a cuscinetti che coprono solo metà della circonferenza di un albero o asse, fornendo supp...

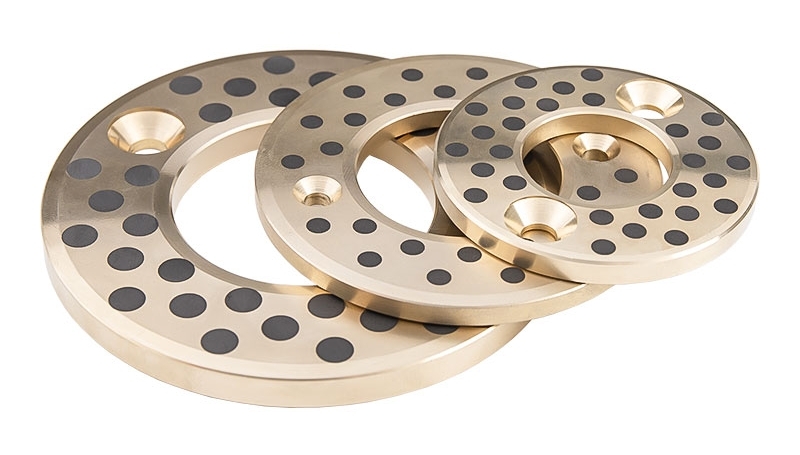

Guarda i detagli Nel preciso mondo dei macchinari, ogni minuscolo componente ha un'enorme responsabilità. La rondella di spinta, un componente apparentemente semplice ma altamente funzionale, è un collegamento cruciale per garantire il funzionamento stabile di vari sistemi idraulici e apparecchiature meccaniche. Dai motori automobilistici ad alta velocità alle apparecchiature aerospaziali di precisione, le rondelle di spinta sono diventate una parte indispensabile dell'industria moderna grazie alle loro proprietà uniche e alla vasta gamma di applicazioni.

Le rondelle di spinta sono in genere realizzate in metalli (come acciaio inossidabile, leghe di rame), polimeri (come politetrafluoroetilene) o materiali in fibra rinforzata. Sono progettati come strutture piatte e simili a disco simili ai cuscinetti diritti ma sono specializzati nei carichi assiali. Questo design consente alle rondelle di spinta di eccellere in ambienti con carichi elevati, funzionamento ad alta velocità o movimento intermittente. Inoltre, alcune rondelle di spinta di fascia alta, come a base di rame JTW rondelle di spinta auto-lubrificanti , Incorporare lubrificanti solidi che formano un film lubrificante durante il funzionamento, riducendo ulteriormente il coefficiente di attrito e estendendo la durata di servizio.

Prestazioni del prodotto:

l Resistenza all'usura: le rondelle di spinta subiscono test rigorosi e presentano un'eccellente resistenza all'usura, consentendo un funzionamento stabile a lungo termine in ambienti ad alta velocità e ad alta temperatura e riducendo i tassi di guasto delle apparecchiature.

l Prestazioni di tenuta: il processo di produzione ad alta precisione garantisce che le rondelle di spinta abbiano buoni effetti di tenuta, prevenendo efficacemente le perdite di liquido o gas e le prestazioni del sistema di salvaguardia.

l Capacità di carico: a seconda del materiale e del design, le rondelle di spinta possono resistere a carichi assiali che vanno da alcuni newton a diverse migliaia di newton, soddisfacendo varie esigenze di applicazione.

l Prestazioni auto-lubrificanti: modelli specifici di rondelle di spinta, come le rondelle di spinta auto-lubrificanti a base di rame JTW, hanno proprietà auto-lubrificanti che possono ridurre il coefficiente di attrito a 0,02-0,08, riducendo in modo significativo l'usura ed estendendo la durata delle attrezzature.

Vantaggi del prodotto:

l Alta affidabilità: l'applicazione di rondelle di spinta migliora significativamente la stabilità e l'affidabilità dei sistemi meccanici, riducendo i tempi di inattività a causa di attrito e usura.

l Vita lunga: grazie alla loro eccellente resistenza all'usura e caratteristiche di auto-lubrificante, le rondelle di spinta hanno una durata di servizio di diversi anni, riducendo i costi di manutenzione e la frequenza di sostituzione.

l Diversità: le rondelle di spinta sono disponibili in vari materiali, dimensioni e tipi per soddisfare le esigenze di diversi settori e scenari di applicazione e sono supportati i servizi personalizzati.

l Ampia applicabilità: dalla produzione automobilistica all'aerospaziale, dalla produzione chimica alle apparecchiature elettroniche, le rondelle di spinta hanno una vasta gamma di applicazioni e sono una parte indispensabile di molte industrie.

Scenari di applicazione specifici:

l Industria automobilistica: nei componenti chiave come i motori automobilistici, le trasmissioni e gli alberi di azionamento, l'applicazione di rondelle di spinta migliora significativamente l'efficienza meccanica e l'affidabilità, riducendo i tassi di fallimento. Le statistiche mostrano che i motori automobilistici che utilizzano rondelle di spinta di alta qualità possono ridurre i tassi di fallimento di oltre il 30%.

l Produzione di macchinari: in apparecchiature per macchinari di precisione come macchine utensili, stampa e macchine tessili, l'uso di rondelle di spinta riduce l'attrito e l'usura, migliorando l'accuratezza e la stabilità di elaborazione.

l Aerospace: in vari attrezzature ad alta precisione nel campo aerospaziale, come motori, carrello di atterraggio e sistemi idraulici, le rondelle di spinta assicurano un funzionamento sicuro delle attrezzature con le loro eccezionali prestazioni e affidabilità.

l Industria chimica: nelle apparecchiature chimiche come pompe, valvole e reattori, le rondelle di spinta non solo impediscono perdite di media corrosivi, ma migliorano anche la resistenza alla corrosione dell'attrezzatura e la durata di servizio.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. produce la serie JTW/JTWN di rondelle di spinta, che utilizzano ottone ad alta resistenza incorporate con grafite di alta qualità per migliorare ulteriormente la durata del prodotto e fornire una forte protezione per le tue attrezzature. Per gli ordini, contattare: [email protected] .

I semicuscinetti autolubrificanti MXB-JFFB si riferiscono a cuscinetti che coprono solo metà della circonferenza di un albero o asse, fornendo supp...

Guarda i detagli

Il cuscinetto in bronzo fuso autolubrificante MXB-JDBU è un prodotto lubrificante solido ad alte prestazioni intarsiato con lubrificante solido in ...

Guarda i detagli

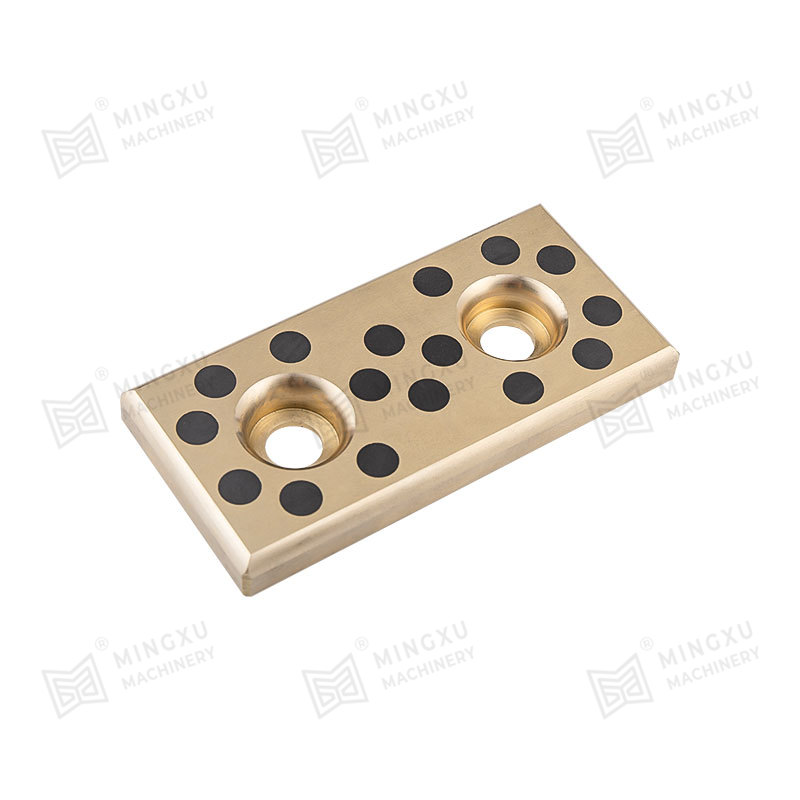

Lo skateboard MXB-JESW è uno skateboard per carichi pesanti resistente all'usura con 2 fori e 4 fori. È un prodotto standardizzato ed è compat...

Guarda i detagli

Le attrezzature utilizzate nei macchinari minerari sono soggette a grave usura. Al fine di prolungare la durata dell'attrezzatura, le piastre ...

Guarda i detagli

La boccola di guida standard MGB9834 DIN9834 è conforme allo standard DIN9843 ed è adatta per matrici per stampaggio automobilistico europeo. È pro...

Guarda i detagli

La boccola di guida standard MGB61 NAAMS è una soluzione affidabile per applicazioni di guida precise e fluide. Questa boccola di guida è progettat...

Guarda i detagli

MX2000-1 graphite embedded alloy bearing, MX2000-1 graphite scattered alloy bearing is an improved product of JF800 bimetallic bearing. It has the pre...

Guarda i detagli

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

Guarda i detagli

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

Guarda i detagli

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

Guarda i detagli

Contattaci